HELU KABEL GmbH

Booth number: 3321

helukabel.de/

About us

1. Company Introduction:

Helukabel is a leading German manufacturer of cables, wires, and cable accessories, founded in 1978. For over four decades, we have provided high-quality, innovative, and customized solutions for a vast spectrum of industries. Our core strength lies in our deep engineering expertise, in-house manufacturing, and a global distribution network, ensuring reliable performance and technical support worldwide. We are certified to international standards, including VDE, UL/CSA, and GOST, guaranteeing product excellence and safety.

2. Detailed Product Presentations:

A. Cables for Automation & Dynamic Applications:

Product Range: Servo and motor cables, control cables, hybrid cables (power + data), and highly flexible cables for continuous-motion applications.

Key Features: Designed for use in drag chains (cable carriers), robotic systems, and automated machinery. They feature exceptional flexibility, resistance to oil, chemicals, and abrasion, and are engineered for millions of bending cycles.

Series Examples: TOPFLEX®, ROBOTFLEX®, TOPSERV®, MULTIFLEX®.

B. HELUCHAIN® Drag Chain Systems:

Product Range: A comprehensive portfolio of cable carriers (drag chains) designed to protect cables and hoses in automated, moving applications. Available in plastic, steel, and hybrid designs to suit various loads, speeds, and environmental conditions.

Key Features: Low wear, smooth operation, and high torsional stability. We offer complete solutions, including guiding troughs and support systems, and provide pre-assembled systems (from Level 1 to Level 3) for easy integration and reduced installation time.

Series Examples: HELUCHAIN® PLASTIC LINK, HELUCHAIN® STEEL LINK, HELUCHAIN® HYBRID LINK.

C. Data & Network Cables:

Product Range: Industrial Ethernet cables (Cat. 5e to Cat. 7), fieldbus cables (PROFIBUS, PROFINET), fiber optic cables, and coaxial cables.

Key Features: Shielded for excellent resistance to electromagnetic interference (EMI), ensuring reliable, high-speed data transmission in harsh industrial environments. Many are also designed for flexibility and use in drag chains.

Series Examples: HELUKAT®, TRONIC®, HELUOPTIC®.

D. Cables for Energy & Infrastructure:

Product Range: Includes solar cables (PV), wind power cables, medium-voltage power cables, and standard building installation wires.

Key Features: Products are resistant to weather, UV radiation, ozone, and extreme temperatures. Our SOLARFLEX® series, for example, is specifically designed for photovoltaic systems, while HELUWIND® cables are built for the demanding conditions of wind turbines.

E. Special Application Cables:

Product Range: Customized solutions for unique challenges, including halogen-free flame-retardant cables, high-temperature cables, shipboard cables, and cables for event technology (sound & light).

Key Features: Engineered to meet specific safety and performance standards for niche applications, from offshore platforms to public venues and transportation systems.

Series Examples: HELUTHERM® (high-temp), HELUSOUND®, HELULIGHT®.

3. Our Value Proposition:

We are more than just a cable supplier. We are a solution provider. Our team offers expert technical consultation and specializes in developing custom-designed cable and drag chain systems tailored to your specific application, ensuring optimal performance, longevity, and cost-efficiency.

Address

Schlosshaldenstr. 10

71282 Hemmingen

Germany

E-mail: thorino.johansen@helukabel.co.id

Phone: +49 7150 92090

Internet: www.helukabel.de

Pulo Kambing II No.26

13930 East Jakarta

Indonesia

E-mail: thotino.johansen@helukabel.co.id

Phone: +62 21 22488299

Internet: www.helukabel.co.id/id-en/Home

Contact person:

Mr Thorino Johansen

E-mail: thorino.johansen@helukabel.co.id

JZ-500 / OZ-500

Details

Cable Structure

Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Core insulation: PVC, compound type Z 7225

Core identification acc. to DIN VDE 0293-334, black cores with consecutive labeling in white digits

Protective conductor: starting with 3 cores,

G = with protective conductor GN-YE, in the outer layer,

x = without protective conductor (OZ)

Cores stranded in layers with optimal lay lengths

Outer sheath: PVC acc. to DIN VDE 0207-363-4-1 / DIN EN 50363-4-1 (compound type TM2)

Sheath colour: grey (RAL 7001)

Length marking: in metres

Properties

largely resistant to: oil,

for details, see "Technical Information"

conditionally torsional

conditionally suitable for drag chains

the materials used during manufacturing are cadmium-free, contain no silicone and are free from substances harmful to the wetting properties of lacquers

Tests

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC

VDE-Reg.-No. 7032, valid for temperature range up to +70°C

Notes

the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

please note "cleanroom qualification" in your order

Application

Used for flexible applications involving medium mechanical stress with free movement, without tensile stress and without forced motion control in dry, damp and wet rooms, however, not suitable for outdoor use. Used as a connection and control cable in machine tools, assembly lines and conveyor belts, production lines, in plant construction, air-conditioning technology, in smelters and steel mills. Select PVC compounds guarantee good flexibility, efficient and quick installation.

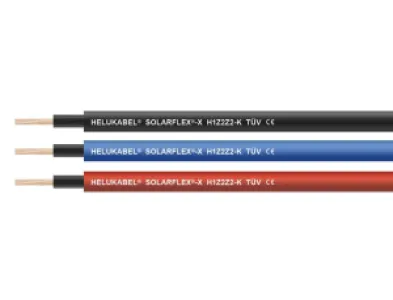

Sloar Cables - SOLARFLEX®-X H1Z2Z2-K

Technical Data

Cross-linked single core cable acc. to DIN VDE 0283-618 / DIN EN 50618Temperature rangefixed -40°C to +90°CPermissible operating temperature of the conductor+120°CNominal voltageAC U0/U 1000/1000 V

DC U0/U 1500/1500 VTest voltage6500 VMinimum bending radiusfixed 5x Outer-Ø

Details

Cable Structure

Copper wire tinned, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Core insulation: cross-linked compound

x = without protective conductor

Outer sheath: cross-linked compound

Sheath colour: see datasheet

Properties

resistant to: UV radiation, ozone, weathering effects, water

for outdoor use

direct burial

halogen-free

Tests

halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

smoke density acc. to DIN VDE 0482-1034-1+2 / DIN EN 61034-1+2 / IEC 61034-1+2

UV-resistant acc. to DIN VDE 0283-618 / DIN EN 50618 Appendix E

ozone-resistant acc. to DIN VDE 0283-618 / DIN EN 50618

weather-resistant acc. to DIN VDE 0283-618 / DIN EN 50618 Appendix E

water-resistant acc. to DIN VDE 0285-525-2-21 / DIN EN 50525-2-21 Appendix E

DC Voltage resistance of the insulation acc. to DIN VDE 0283-618 / DIN EN 50618 Tab. 2

certifications and approvals:

EAC

TÜV Rheinland

Notes

the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Application

SOLARFLEX®-X H1Z2Z2-K is used for wiring solar modules. Suitable for direct burial; recommendation: laying in pipes. Not suitable for permanent installation in water. The maximum permissible DC voltage of the system in which the cable is installed must not exceed 1.8 kV. The cable is suitable for use in and on devices and systems with protective insulation (protection class II). Minimum temperature during installation and handling: -25 °C.

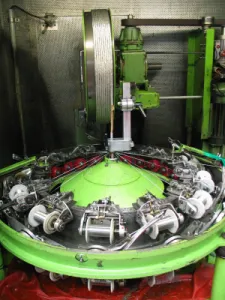

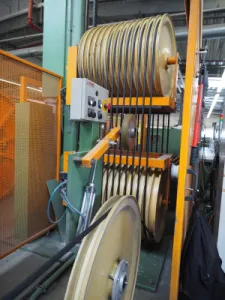

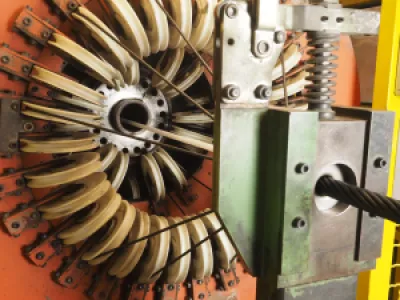

Helu Chain System

HELUCHAIN® SYSTEM is a modular system from HELUKABEL for drag chain applications with linear movements. It combines perfectly coordinated drag chains, highly flexible cables—fully assembled, standard and custom designs available on request—and appropriate accessories into optimised complete solutions. From the most basic combination of drag chain and cable, to a completely integrated and assembled drag chain system with accessories, our clearly structured, three-tier configuration (assembly levels 1-3) makes it possible for the HELUCHAIN® SYSTEM to be precisely tailored to each individual application. For maximum efficiency and reliability, we supply everything from a single source—precisely manufactured, rigorously inspected, and ready for immediate installation.

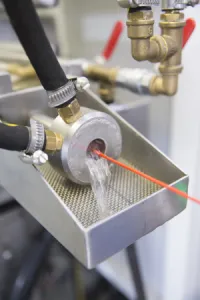

Cable Glands

Cable glands are an essential part of electrical installations. They secure and protect cables in enclosures, machines and systems. Depending on the application, they offer different degrees of protection (IP66, IP67, IP68, IP69K), meet safety requirements for potentially explosive atmospheres (ATEX) and provide EMC protection.

Mining Cables - HELUPOWER® H07RN-F LS0H

Technical Data

Rubber connection cable acc. to DIN VDE 0285-525-2-21 / DIN EN 50525-2-21Temperature rangeflexible -40°C to +90°C

fixed -50°C to +90°CPermissible operating temperature of the conductor+90°CShort circuit temperature at the conductor+250°CNominal voltageAC U0/U 450/750 VMax. permissible operating voltagealternating current (AC) conductor/earth 476 V

three-phase alternating current (AC) conductor/conductor 825 V

direct current (DC) conductor/earth 619 V

direct current (DC) conductor/conductor 1238 VTest voltage core/core2500 VMinimum bending radiusflexible 6x Outer-Ø

fixed 4x Outer-Ø

Details

Cable Structure

Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Core insulation: Special rubber

Core identification acc. to DIN VDE 0293-308,

1 core(s): black

2 - 5 core(s): colour coded

7 - 12 core(s): black cores with consecutive labeling in white digits

Protective conductor: starting with 3 cores,

G = with protective conductor GN-YE, in the outer layer,

x = without protective conductor

Cores stranded in layers with optimal lay lengths

Outer sheath: Special rubber

Sheath colour: black

Properties

resistant to: oil, UV radiation, ozone, weathering effects, lubricating oils, greases

for outdoor use

halogen-free

Tests

halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1

corrosiveness of combustion gases acc. to DIN VDE 0482-754-2 / DIN EN 60754-2 / IEC 60754-2

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

smoke density acc. to DIN VDE 0482-1034-1+2 / DIN EN 61034-1+2 / IEC 61034-1+2

oil-resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404

ozone-resistant acc. to DIN VDE 0473-811-403 / DIN EN 60811-403

certifications and approvals:

HAR

EAC

Notes

the conductor is metrically (mm²) constructed, AWG numbers are approximated, and are for reference only

Application

Halogen-free rubber sheathed cables for use with medium mechanical stress in dry, damp, wet rooms and outdoors. Can only be used in stagnant waters (also in salt water) up to a water depth of 100 m (AD8) and a water temperature of min. +5°C. When installed in pipes or similar closed systems, the use of the cable is permitted up to and including 1000 V AC voltage or up to 750 V DC voltage against earth.