Robert Röntgen GmbH & Co. KG

Booth number: 8122

www.roentgen-saw.com

About us

Founded in 1899, Robert Röntgen GmbH & Co. KG is based in Remscheid, at the heart of the German tool industry.

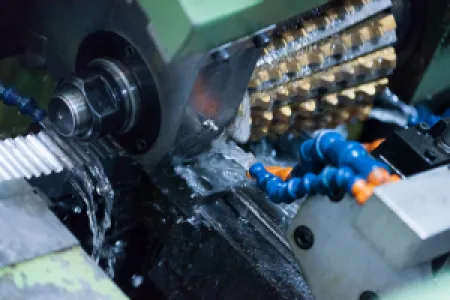

The continuous improvement and development process of our products made RÖNTGEN to one of the leading manufacturers of bimetal and carbide band saw blades. This market position is based on the goal to produce highest quality based on the philosophy and procedures of DIN EN ISO 9001:2008.

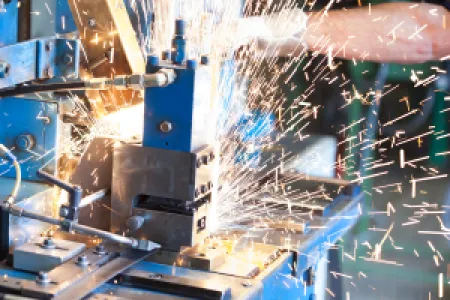

Our recently extended and upgraded production plant is equipped with state of the art manufacturing and testing facilities that keep us ahead of the industry. Our customers benefit from the process and applications knowledge of our highly experienced and technically qualified team. By applying the principles of continuous improvement we maximize the cutting performance of our products.

Address

Auf dem Knapp 44

42855 Remscheid

Germany

E-mail: s.jung@roentgen-saw.com

Phone: +49 2191 37301

Internet: www.roentgen-saw.com

Kawasan Griya Idola Industrial Park Blok Y No. 16 Jl. Raya Serang Km. 12

15710 Desa Bitung Jaya, Kec. Cikupa Kab. Tangerang, Banten

Indonesia

E-mail: sales@metaltechindonesia.com

Phone: +49 021 55657435

Internet: www.metaltechindonesia.com

Contact person:

STEPHAN JUNG

E-mail: s.jung@roentgen-saw.com

Products & Services

Robert Röntgen Band Saw Blades – Product & Performance Overview

Product Range

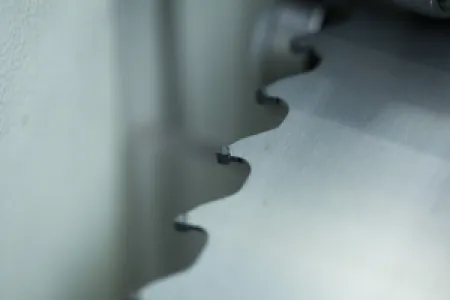

Bi-Metal Band Saw Blades

Wide selection for cutting steel, stainless steel, tool steel, non-ferrous metals.

Long blade life and excellent cutting performance.

Designed for general purpose as well as high-performance applications.

Carbide Band Saw Blades

For extremely hard and abrasive materials.

Suitable for heat-resistant alloys, titanium, Inconel, and hardened steels.

Superior wear resistance and maximum precision.

Carbon Steel Band Saw Blades

Cost-effective solutions for cutting wood, plastics, and non-ferrous metals.

Flexible back and hardened teeth for durability.

Special Solutions

Customized tooth geometries and dimensions.

Application-specific blade design to optimize productivity.

Performance Advantages

High Cutting Efficiency – Reduced cutting time through optimized tooth geometry.

Extended Blade Life – State-of-the-art materials and precision manufacturing.

Consistent Quality – Certified according to DIN EN ISO 9001:2008.

Versatile Applications – From workshops to industrial large-scale production.

Customer Support – Technical advice and application expertise from experienced specialists.

Industries Served

Steel production and processing

Aerospace and automotive industry

Tool and mold making

Metal fabrication and workshops

Foundries and machine shops